Heterodyne Kelvin Probe Force Microscopy

Heterodyne KPFM

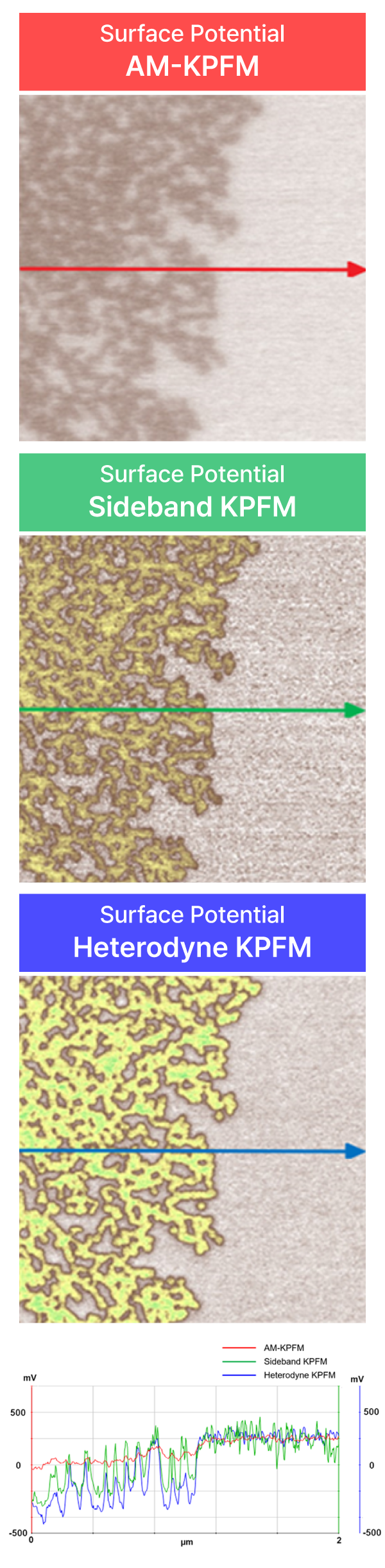

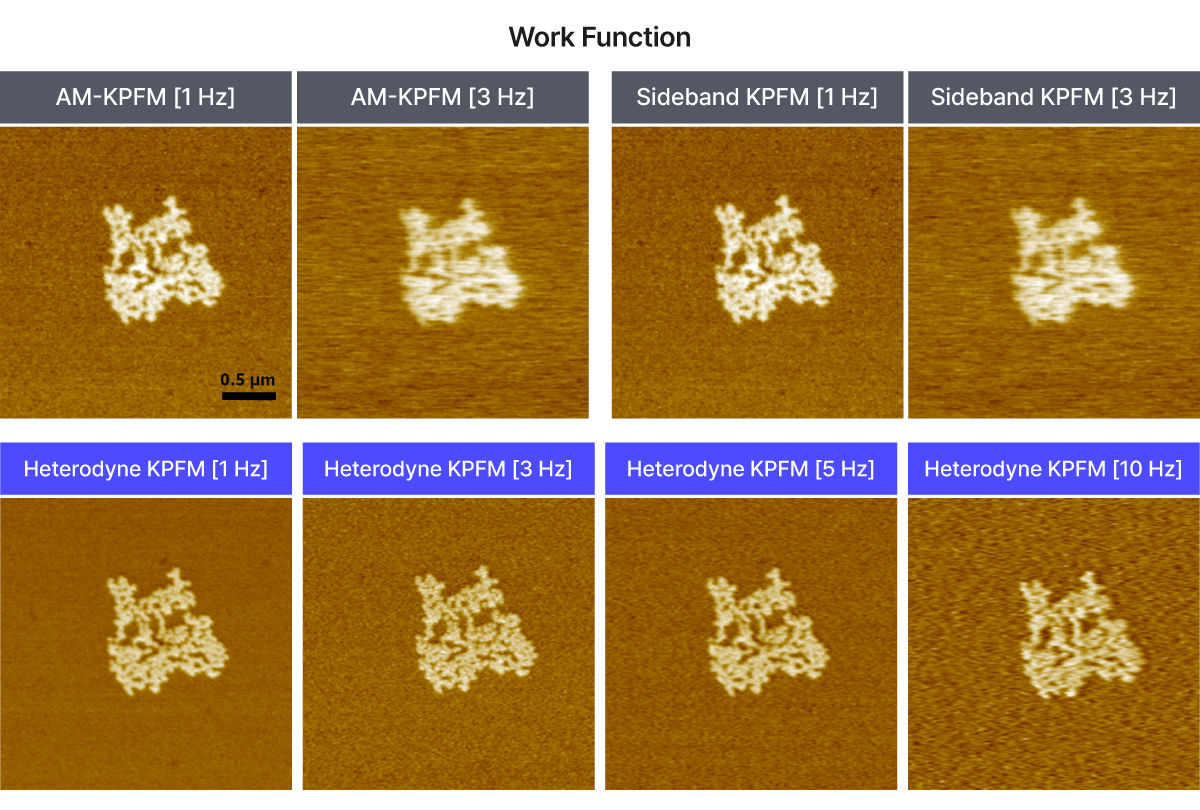

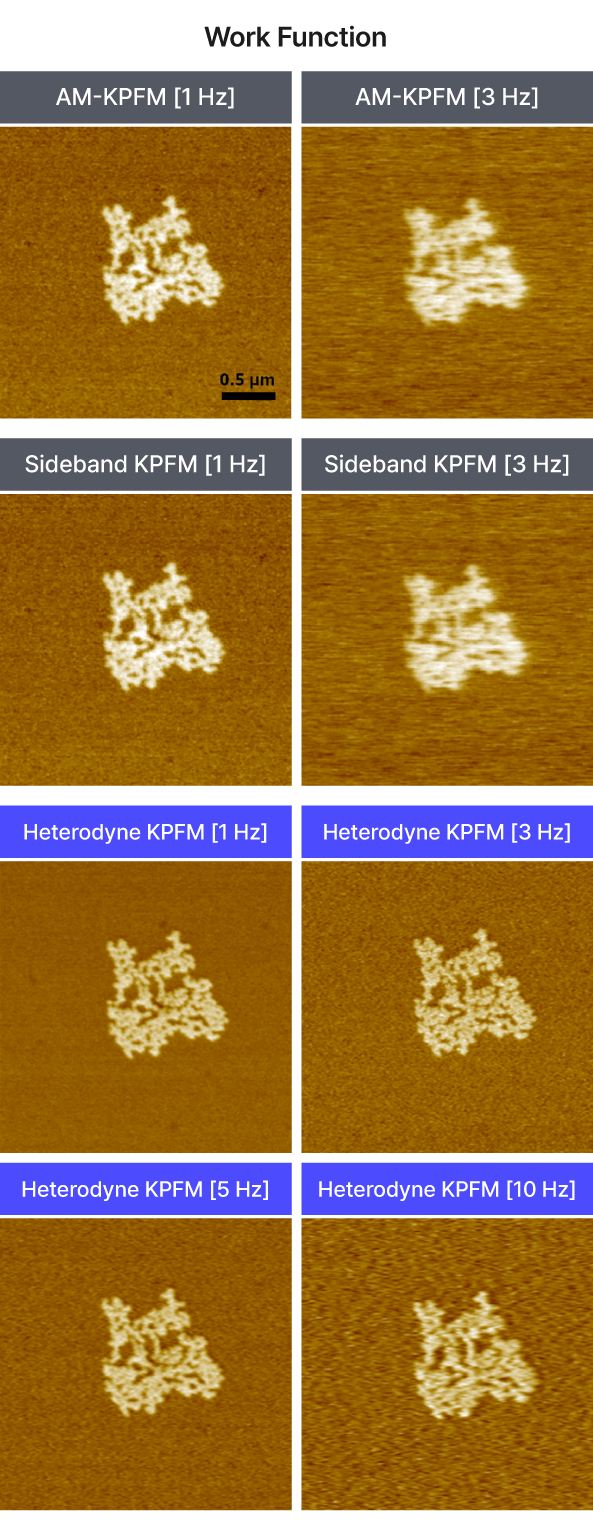

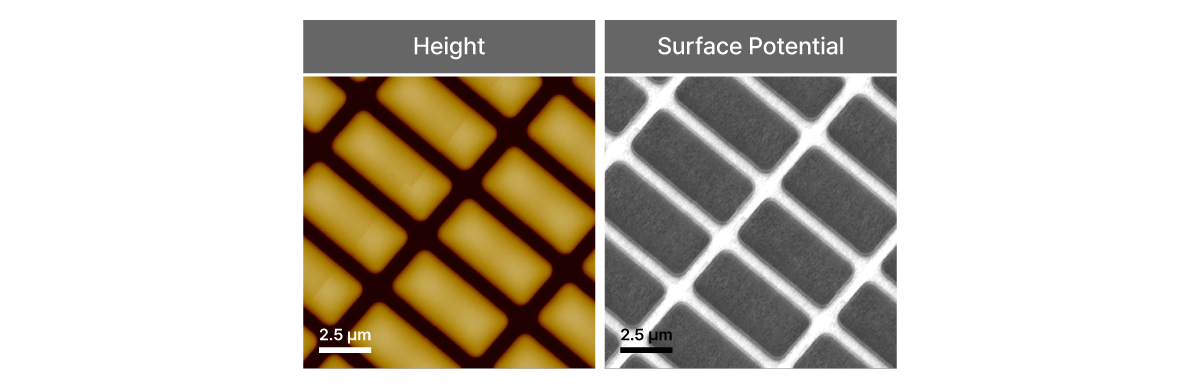

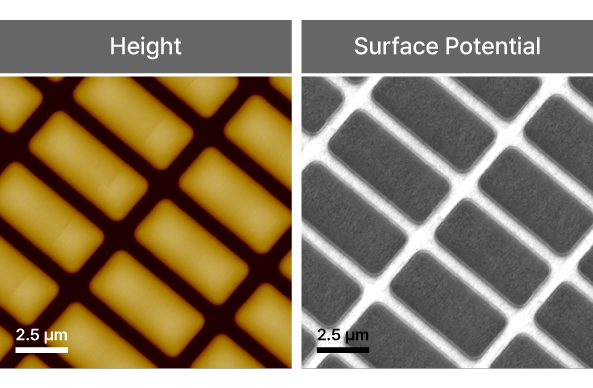

Superior surface potential detection with high spatial resolution by frequency mixing away from cantilever resonance, reducing noise and topography crosstalk